FREE estimates! Call 434-239-5386

Expert Diesel Exhaust & Aftertreatment Repair Specialists

At Bee Line Transport, we recognize the importance of ensuring your diesel-powered vehicles operate efficiently while adhering to strict emissions standards. This is not only essential for your business but also for the environment. We take pride in offering comprehensive diesel exhaust and aftertreatment system repair services in Lynchburg, Virginia. With our unwavering commitment to excellence and decades of experience in this field, we have established ourselves as the trusted partner for individuals and businesses reliant on diesel engines.

Our primary objective is crystal clear: to deliver top-notch solutions for diesel exhaust control and aftertreatment systems, ensuring that your vehicles remain in optimal condition and minimizing their environmental footprint. Whether you are grappling with emissions compliance issues or need professional maintenance for your aftertreatment systems, Bee Line Transport is your dedicated partner, providing precision, efficiency, and a solid commitment to sustainability.

Understanding Diesel Exhaust Systems

Diesel exhaust systems and maintenance are essential facets of diesel-powered vehicles and machinery. Regular maintenance and repair of diesel exhaust systems are critical for optimal engine performance, emissions compliance, and safety. Neglecting these systems can result in reduced fuel efficiency, increased emissions, and potential safety hazards.

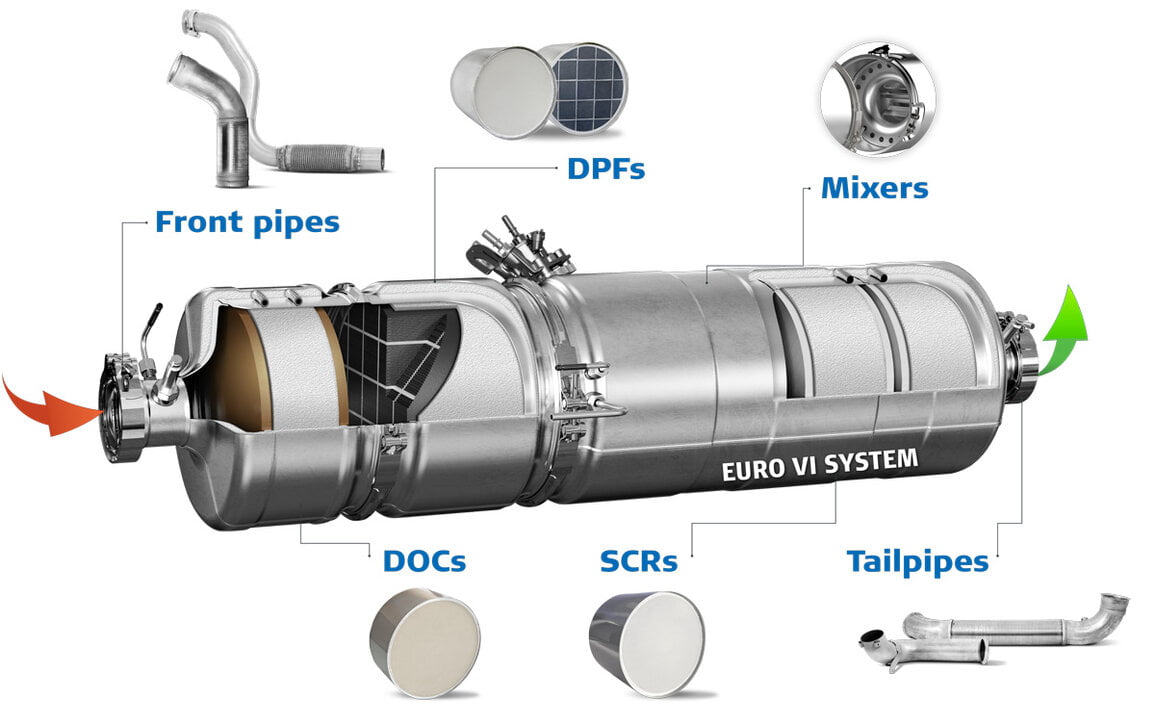

Diesel exhaust systems include the exhaust manifold, turbocharger, catalytic converter, diesel particulate filter (DPF), and muffler. These elements work together to direct exhaust gasses safely out of the vehicle. Diesel engines emit pollutants such as nitrogen oxides (NOx), particulate matter, and hydrocarbons. Diesel exhaust systems are equipped with technologies like SCR, DPF, and EGR to minimize these emissions and comply with environmental standards.

Diesel exhaust systems can suffer from issues like clogs in the DPF, leaks in the exhaust components, and catalytic converter malfunctions. Understanding these common problems is crucial for timely repairs. Repairing diesel exhaust systems ensures that emission control mechanisms are functioning correctly. This helps meet environmental standards and contributes to cleaner air quality and reduced health risks.

Understanding Aftertreatment Systems

Aftertreatment systems are critical to modern diesel engines designed to reduce harmful emissions. These systems treat exhaust gasses after they leave the engine, ensuring the emissions meet stringent environmental standards. Aftertreatment is essentially the “cleanup crew” for diesel engine exhaust

Key Components of an Aftertreatment System

Three key components make up an aftertreatment system:

- Diesel Particulate Filter (DPF): The DPF is tasked with trapping and removing particulate matter, such as soot and ash, from the exhaust gasses. It captures these particles and periodically regenerates (burning off) them to maintain optimal performance.

- Selective Catalytic Reduction (SCR): SCR systems use a catalyst, typically containing urea (AdBlue or DEF), to convert nitrogen oxides (NOx) into harmless nitrogen and water. This process is highly effective in reducing NOx emissions.

- AdBlue/DEF (Diesel Exhaust Fluid): AdBlue or DEF is a solution of urea and deionized water. It is injected into the exhaust stream before the SCR catalyst, where it chemically reacts with NOx emissions, breaking them down into nitrogen and water vapor.

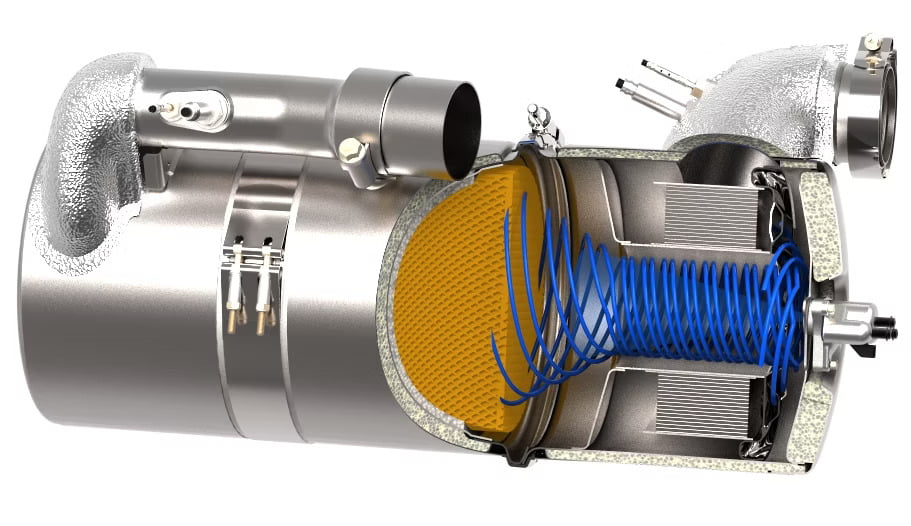

How Aftertreatment Systems Work

Aftertreatment systems work in a well-orchestrated sequence to reduce emissions:

- Diesel Particulate Filter (DPF): As exhaust gasses pass through the DPF, particulate matter is trapped within the filter's porous structure. Periodically, the DPF initiates a regeneration process where it heats up and burns off the collected soot and ash. This process ensures the DPF's longevity and efficiency.

- Selective Catalytic Reduction (SCR): Before reaching the SCR catalyst, diesel exhaust fluid (AdBlue or DEF) is injected into the exhaust stream. As the exhaust gasses pass over the SCR catalyst, a chemical reaction occurs, converting NOx emissions into nitrogen and water vapor.

The combined effect of these components is a substantial reduction in harmful emissions, making diesel engines more environmentally friendly and compliant with strict emissions standards.

Signs of Diesel Emissions & Aftertreatment Issues

Identifying the signs of diesel exhaust and aftertreatment issues is of utmost importance in ensuring your diesel-powered vehicle’s optimal performance and dependability. Below are several prevalent indicators to be mindful of:

- Decreased Fuel Efficiency: A noticeable drop in fuel efficiency may signal problems within the exhaust and aftertreatment systems, impacting overall engine performance.

- Excessive Smoke: The emission of excessive smoke, often of unusual color or density, can be a sign of issues in the exhaust and aftertreatment components.

- Unusual Odors: Unpleasant or abnormal odors emanating from the exhaust may indicate problems.

- Loud Exhaust Noise: A significant increase in exhaust noise can indicate underlying exhaust and aftertreatment concerns.

- Warning Lights and Indicators: Several dashboard warning lights and indicators may illuminate, including the Check Engine Light, DPF Warning Light, AdBlue/DEF Indicator, and Emissions Warning signs. These are clear signals of potential problems in the exhaust and aftertreatment systems.

By staying vigilant and recognizing these telltale signs, you can promptly address any diesel exhaust and aftertreatment issues, ensuring your diesel vehicle’s continued efficiency and reliability.

Consequences of Diesel Exhaust Issues

Diesel emissions issues can substantially impact your vehicle’s performance. You might notice:

- Reduced Power: Issues in the aftertreatment system or exhaust components can cause a decrease in engine power and responsiveness.

- Increased Emissions: A malfunctioning aftertreatment system may lead to elevated emissions levels, resulting in non-compliance with emissions regulations.

- Poor Idle or Stalling: Emissions control issues can cause rough idling or stalling, affecting the vehicle’s overall drivability.

- Overheating: In some cases, problems within the aftertreatment system can lead to engine overheating, posing a risk to the vehicle’s health and longevity.

It’s essential to promptly address any of these signs or warning indicators to ensure your diesel vehicle continues to operate efficiently, remains compliant with emissions standards, and maintains its overall performance and reliability. Regular maintenance and timely repairs can prevent more extensive and costly issues.

Diesel Exhaust & Aftertreatment Repair Process

Diesel exhaust and aftertreatment repair is a systematic procedure to restore the efficiency, emissions compliance, and overall functionality of a diesel-powered vehicle’s exhaust and aftertreatment systems. The process involves several key steps to diagnose, address, and rectify issues. Here’s an overview of the diesel exhaust repair process:

Inspection and Troubleshooting

Our experienced technicians begin the process with a comprehensive inspection and troubleshooting of the aftertreatment system. This involves a detailed assessment of the components, including the Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR) system, AdBlue/DEF injection system, and associated sensors. We use state-of-the-art diagnostics to identify any issues or malfunctions.

Component Repair and Replacement

Once we've pinpointed the problems within the aftertreatment system, our skilled technicians proceed with the necessary component repair or replacement. This may involve repairing damaged parts, cleaning the DPF, regenerating the filter, or replacing malfunctioning components to restore the system's functionality.

Emissions Testing and Compliance

After completing the repairs and replacements, we conduct emissions testing to ensure your vehicle complies with emissions standards. This testing verifies that the aftertreatment system effectively reduces emissions, mainly nitrogen oxides (NOx), and achieves regulatory compliance. We take pride in delivering vehicles that meet emissions standards and minimize their environmental impact.

Quality Assurance

Quality assurance is a fundamental part of our aftertreatment repair process. We conduct rigorous quality checks to ensure all repaired or replaced components function correctly. Our technicians pay close attention to correctly integrating software updates and calibrations to optimize your vehicle's performance and emissions control capabilities.

Road Testing

Many diesel exhaust repair processes include a road test to assess the vehicle's performance under real-world conditions. This test helps ensure that the exhaust system operates seamlessly and that the vehicle's efficiency and emissions levels are within acceptable parameters.